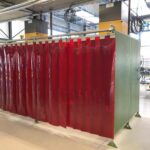

At Cepro, we’re always looking for ways to improve our product range. To enhance clarity and functionality, we’ve recently made some updates: our transparent green welding curtains now feature a lighter, more transparent shade, and we’ve introduced new names for all our welding light protective products.

What’s changed?

The updated transparent green color is now lighter and offers greater transparency. Additionally, we’ve renamed all our welding light protective products to better reflect their specific properties, such as transparency and color intensity.

Here’s an overview of the updates:

| Old Name | New Name |

| Cepro Orange-CE | Cepro Orange Transparent |

| Cepro Green-9 | Cepro Dark Green non-transparent |

| Cepro Green-6 | Cepro Green Transparent |

| Cepro Bronze-CE | Cepro Bronze Transparent |

What stays the same?

The quality, safety, and durability you’ve come to expect from Cepro remain unchanged. These updates are purely visual and linguistic, designed to make it easier for you to identify the right curtain for your workspace.

Important:

Despite the changes in color and names, all our welding light protection products still comply with the ISO EN 25980 standard, as you have come to expect from us.

You’ll start noticing these changes in your next order. If you have any questions or need assistance, feel free to reach out to us. We’re always here to help!